Magnetic Disc Clutches

Applications

The contactless transmission of torque through claddings of various kinds allows for example:

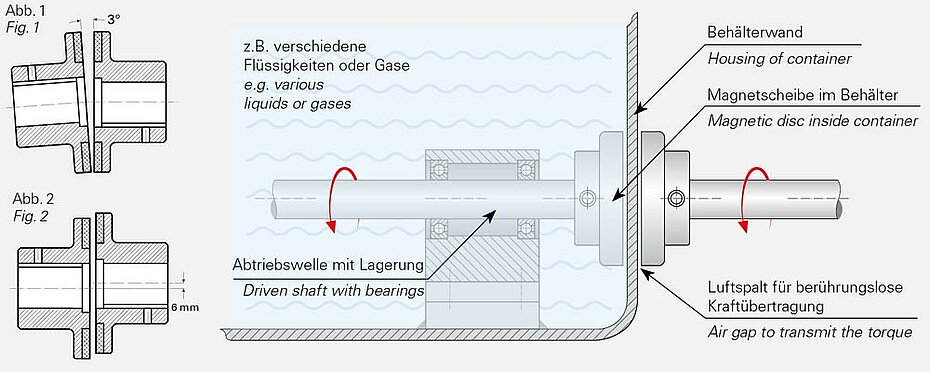

- Power transmission for pumps, agitator assemblies and compressors into closed liquid filled containers

- Power transmission for ventilators in closed containers with gas, steam or similar

- Power transmission for underwater robot- handling

- Transmission of round scale displays into a different medium

- Avoidance of motor vibration transfers

- Uncoupling of load influences at weighing processes

- Standard working temperature range

from -40 to +140°C (special execution

up to +280°C)

Transmission through walls only works with non-magnetic materials.

The magnetic discs can also be parts in hysteresis brakes.

All magnetic disk couplings are made of stainless steel material: 1.4005 / 1.4305 (1.4401 on request)

All laser-welded magnetic disk couplings are made of 1.4401.

How Magnetic Disc Couplings Work:

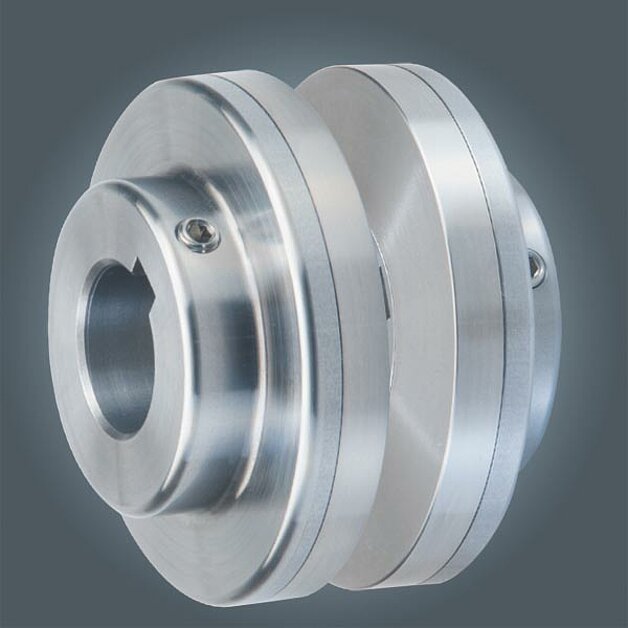

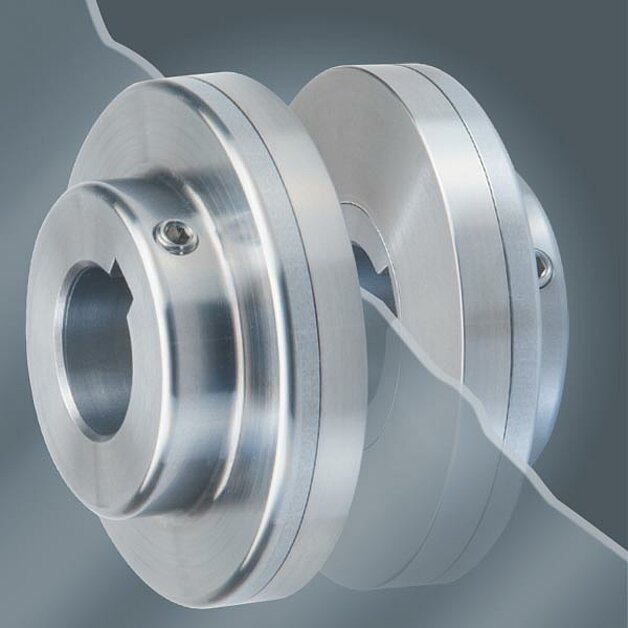

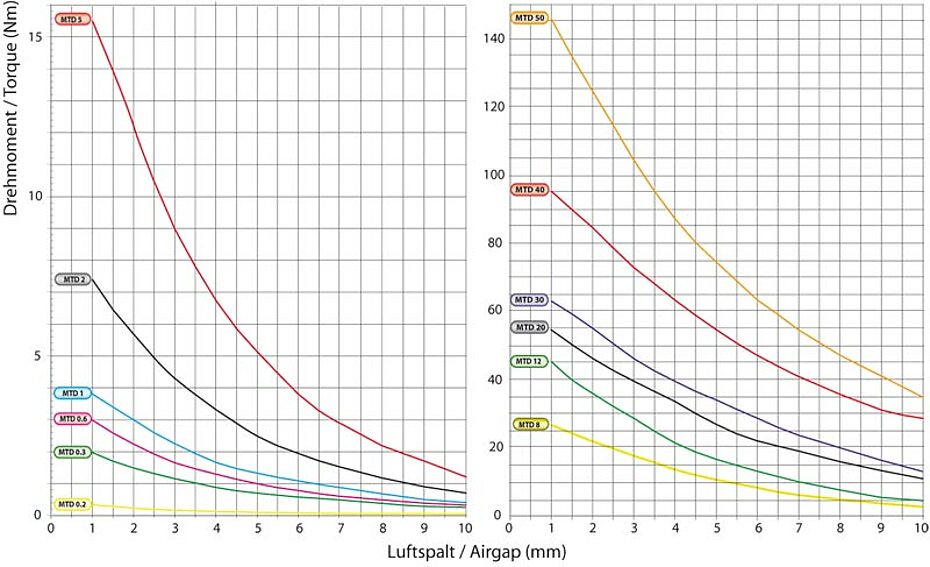

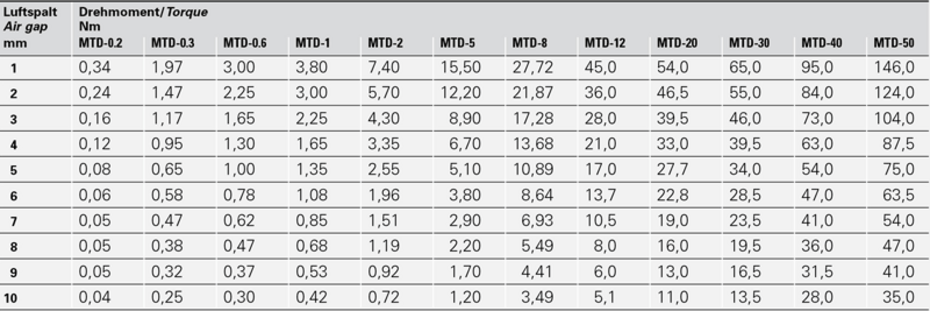

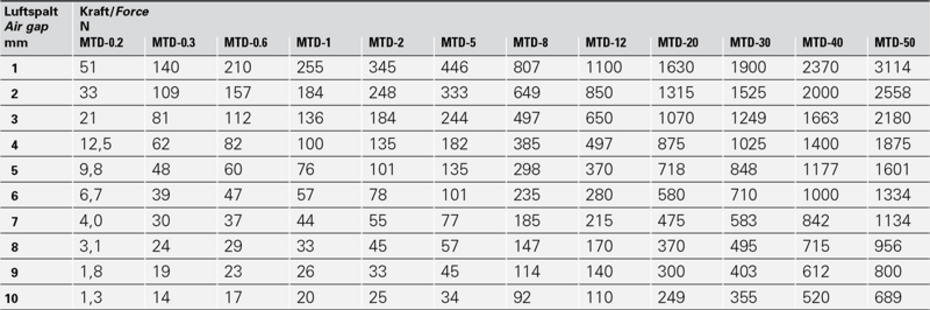

Disk Type Couplings consist of two opposing discs equipped with powerful rare earth magnets. The torque applied to one disc is transferred through an air gap to the other disc.

Because of its simple flat design, you can have angular misalignment of up to 3° (Fig. 1) or parallel misalignment up to 1/4” (Fig. 2) and still transmit nearly full rotational torque.

You can also implement an inexpensive flat barrier to separate the atmospheres or fluids surrounding the two discs. This is our simplest and most versatile application.

The magnetic discs can also be parts in hysteresis brakes.

All dimensions and data specified on this website are subject to improvements and alterations and not always update. If necessary we ask for further inquiry.

• Magnetic Disc Couplings are sold as single halves.

• Weight of a coupling half includes magnets.

• All types are delivered with encapsulated magnets.

• Types MTD-0.2 to MTD-12 are in stock.

• MTD-20 to MTD-50 are manufactured on request.

>Catalog Download (PDF)

for Magnetic Disc Clutsches

(Size approx. 5MB)