Principle and function

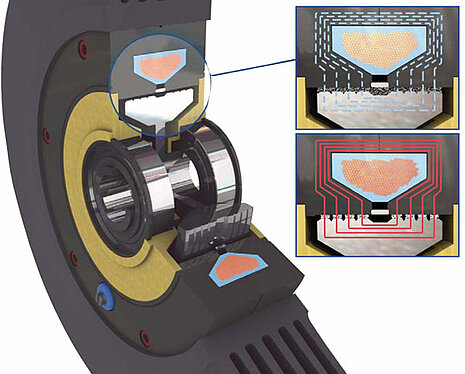

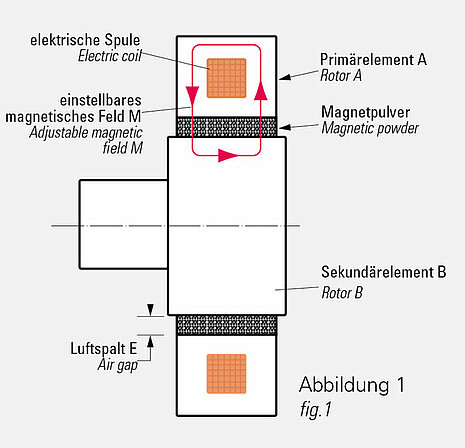

Magnetic particle brakes and clutches are of simple design. Due to their size they produce a high torque compared to for instance hysteresis brakes. They are having two rotors (inner and outer) and an air gap between these two rotors where the magnetic particles are dispersed in. An electric current passing through the coil creates a magnetic field, which aligns the magnetic powder into the gap. The higher the current, the more rigid the connection between the inner and outer rotor becomes. The principle is the same for brake, clutch and torque limitor.

Advantages:

- Noisless work

- Torque directly proportional to current

- Torque independant from r.p.m. (starting from 30 min)

- Strong design, units are able to be used with steady slipping

- High torque range to be controlled (approx 1:50)

Applications:

- Braking

- Torque control, torque limiting

- Tension control at winding, unwinding

- Starting clutch operation

- Calculated braking and starting of certain masses and inertias

Configurator

Our service to you:

with the >Questionair you can get more detailed information about our products.

>Catalog-Download (PDF)

Magnetic Particle Brakes and Clutches

(File size ca. 12MB)