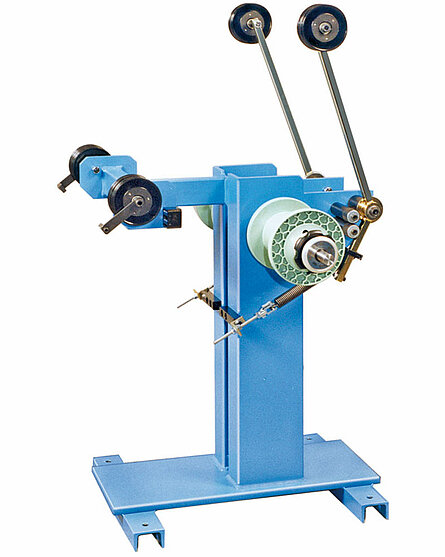

AT-160/355YT

This Tangential Douple Payoff is equipped with an adjustable hysteresis brake for manual tension adjusting. Also there are dancer accumulators for start/stop use. The pulleys on the dancer accumulator are of steel material or of ceramic with plastic flanges dependable on the application. There are cross rollers mounted at the input of the dancers.

Flange Ø: 200 - 355 mm

Multiwire: 3 x 0,1 - 12 x 0,25

Ø Cu-, Al wire: 0,3 -1,9 mm

Ø Steelwire hard: max. 0,8 mm

Ø Steelwire soft: max. 1,5 mm

Wire speed: max. 250 m/min

Wire tension: min. 4, max. 18 N

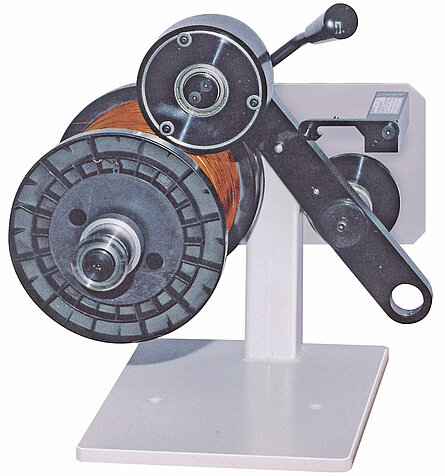

AT-250/300Y

This Tangential Payoff is equipped with an adjustable hysteresis brake for tension braking,

it has a guide free payoff and an extra support for the spool shaft.

Flange Ø: 250 - 300 mm

Multiwire: 5 x 0,1 - 12 x 0,25

Ø Cu-, Al wire: 0,30 - 1,0 mm

Ø Steelwire hard: max. 0,9 mm

Ø Steelwire soft: max. 1,5 mm

Wire speed: max. 300 m/min

Wire tension: min. 4, max. 18 N

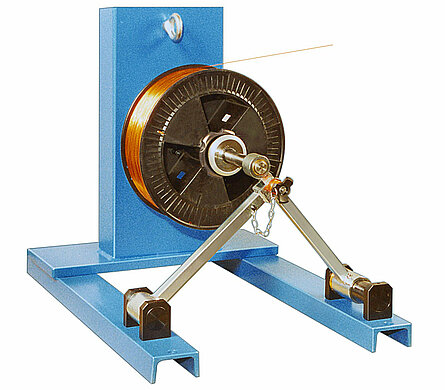

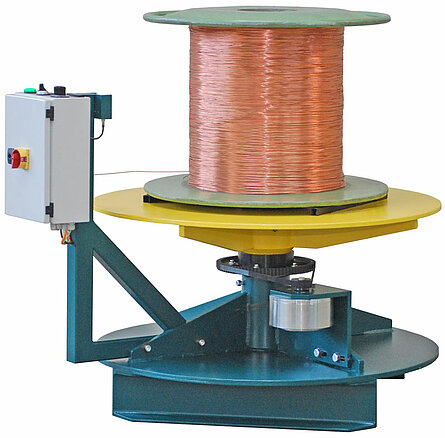

AT-160-355P

This Tangential Payoff is equipped with a magnetic powder brake and a power supply unit for adjustmant of tenseion.

For vertical applications.

Flange Ø: 160 - 355 mm

Ø Cu-, Al wire:0,5 - 3,0 mm

Ø Steelwire hard: 0,3 - 2,0 mm

Ø Steelwire soft: 0,4 - 3,0 mm

Wire speed.: max. 200 m/min

Wire tension: 5 N - 100 N

AT-250Y-600-040R

Adjustable tension 2,3 - 30 N, smallest spooling Ø150mm, greatest flange Ø405mm, max. spool weight 50kg, dimension of spool as customers requirement.

Flange Ø: max. 405 mm

Multiwire: 7 x 0,1 - 8 x 0,32

Ø Cu-, Al wire: 0,3 -1,2 mm

Ø Steelwire hard:max. 1,0 mm

Ø Steelwire soft: max. 1,6 mm

Wire speed: max. 250 m/min

Wire tension: min. 5, max. 30 N

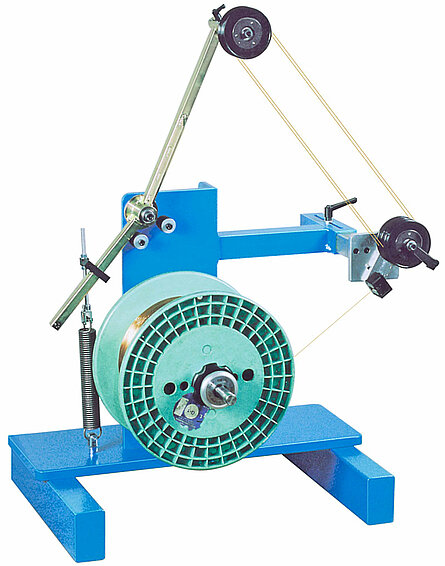

AT-315/500YT

The shown Payoff-unit is equipped with a hysteresis brake to obtain a soft braking. There is also a dancer accumulator, that will keep up the tension in the start/stop use. The spool is kept in position by using an EasyLock unit with axial force on the unwinding spindle.

Flange Ø: max. 315 - 500 mm

Multiwire: 7 x 0,18 - 7 x 0,51

Ø Cu-, Al wire: 0,40 - 1,9 mm

Ø Steelwire hard: max. 0,9 mm

Ø Steelwire soft: max. 1,5 mm

Wire speed: max. 200 m/min

Wire tension: min. 6, max. 35 N

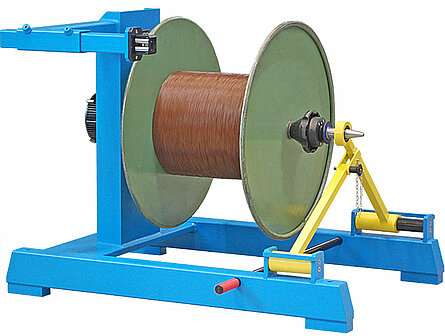

AT-450-630Y

This Tangential Payoff is equipped with a hysteresis brake and and a free payoff without a dancer, with stabilizer especially for thin shafts or spools with small core hole but a high weight.

Optionally with magnetic powder brake for high tensions

Flange Ø: 500 - 800 mm

Ø Cu-, Al wire: 1,0 - 4,5 mm

Ø Steelwire hard: 0,5 - 3,0 mm

Ø Steelwire soft: 0,5 - 3,5 mm

Wire speed: max. 250 m/min

Wire tension: 5 N - 100 N

AT-560-800YE

Driven Tangential Payoff with ultrasonic sensor control

This Pay-off is equipped with equipped with an electrical hysteresis brake and an ultrsonic sensor the control. It controles the constant tension during th pay-off process.

The desired tension is the adjusted via a potentiometer.

The spool is centered by an adapter.

Flange Ø: 500 - 800 mm

Ø Cu-, Al wire: 1,0 - 4,5 mm

Ø Steelwire hard: 0,5 - 3,0 mm

Ø Steelwire soft: 0,5 - 3,5 mm

Wire speed: max. 200 m/min

Wire tension: 5 N - 100 N

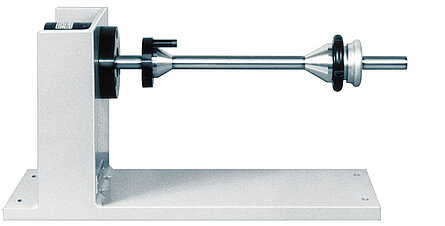

AT-630-800P

The Tangential Payoff is equipped with magnetic powder brake adjustable via power supply for gentle start.

The coil is suspended between two cones.

Flange Ø: 630 - 800 mm

Ø Cu-, Al wire: 0,8 - 4,0 mm

Ø Steelwire hard:0,5 - 2,0 mm

Ø Steelwire soft: 0,5 - 2,5 mm

Wire speed: 250 m/min

Wire tension: 10 - 400 N

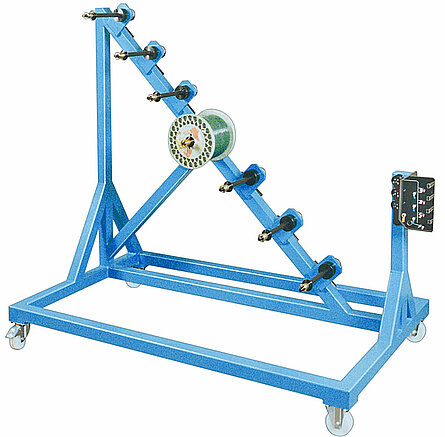

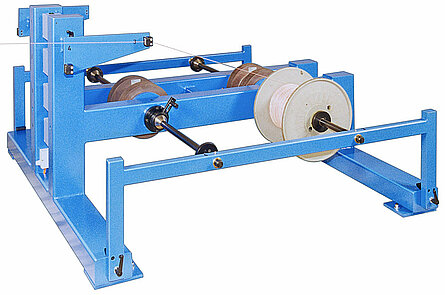

AT12-120/350Y

This payoff frame is equipped with hysteresis brakes and Easylock shaft lock system. Various pulleys, ceramic bushings as well as tungsten-carbide bushings are used depending on the wire material to be payed off.

Flange Ø: 120 - 350 mm

Ø Cu-, Al wire: 0,6 - 2,5 mm

Ø Steelwire hard: max. 1,2 mm

Ø Steelwire soft: max. 1,5 mm

Wire speed: max. 250 m/min

Wire tension: min. 3 N, max. 60 N

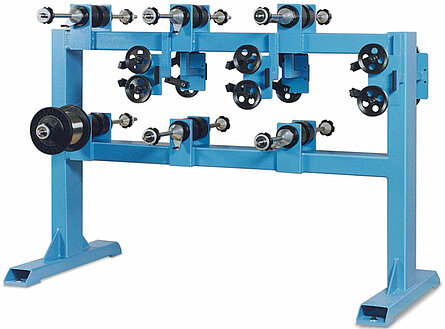

AT4-560P

This Payoff with 4 spoolheads is equipped with magnetic particle brakes. The advantage of this is, that the tension control can also be done with the payoff in operation. There is also a removable shaft-bearing-support for the spoolshaft.

Flange Ø: 450 - 560 mm

Ø Cu-, Al wire: 0,6 - 2,5 mm

Ø Steelwire hard: max. 1,2 mm

Ø Steelwire soft: max. 1,5 mm

Wire speed: max. 300 m/min

Wire tension: min.6 N, max. 150 N

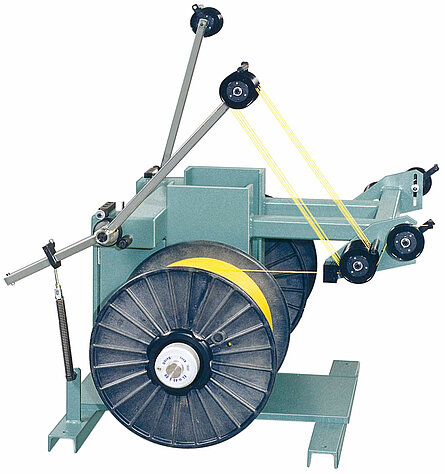

AT2-350/560PTZ

The picture shows a Tangential Payoff with controlled braking of two spoolseats.

The payoff tension stays constant over all diameters by potentiometer control of the dancer that works with a magnetic particle brake.

Flange Ø: 350 - 560 mm

Ø Cu-, Al wire: 0,6 - 3,0 mm

Ø Steelwire hard: max. 2 mm

Ø Steelwire soft:min. 0,4 , max. 1,4 mm

Wire speed:max. 280 m/min

Wire tension: min. 6 N, max. 90 N