Principle and Function

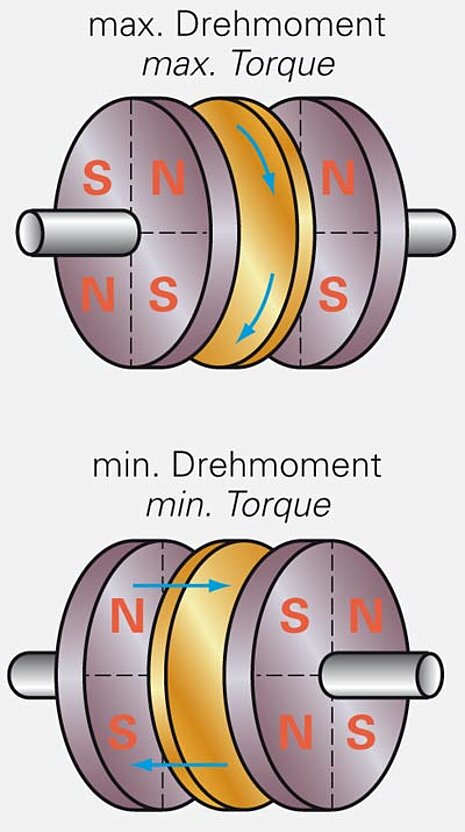

Magnet assemblies (outer discs) surround our hysteresis assembly (center disc). When like poles face each other, they produce maximum magnetic saturation of the hysteresis disc, forcing lines of flux to travel circumferentially through the hysteresis disc. This produces maximum torque. When opposite poles face each other, they produce minimum saturation of the hysteresis disc. The lines of flux travel right through the hysteresis disc. Combinations of adjustment angles between these two extremes gives infinite adjustability. Because there are no contacting surfaces, the setting can be maintained indefinitely.

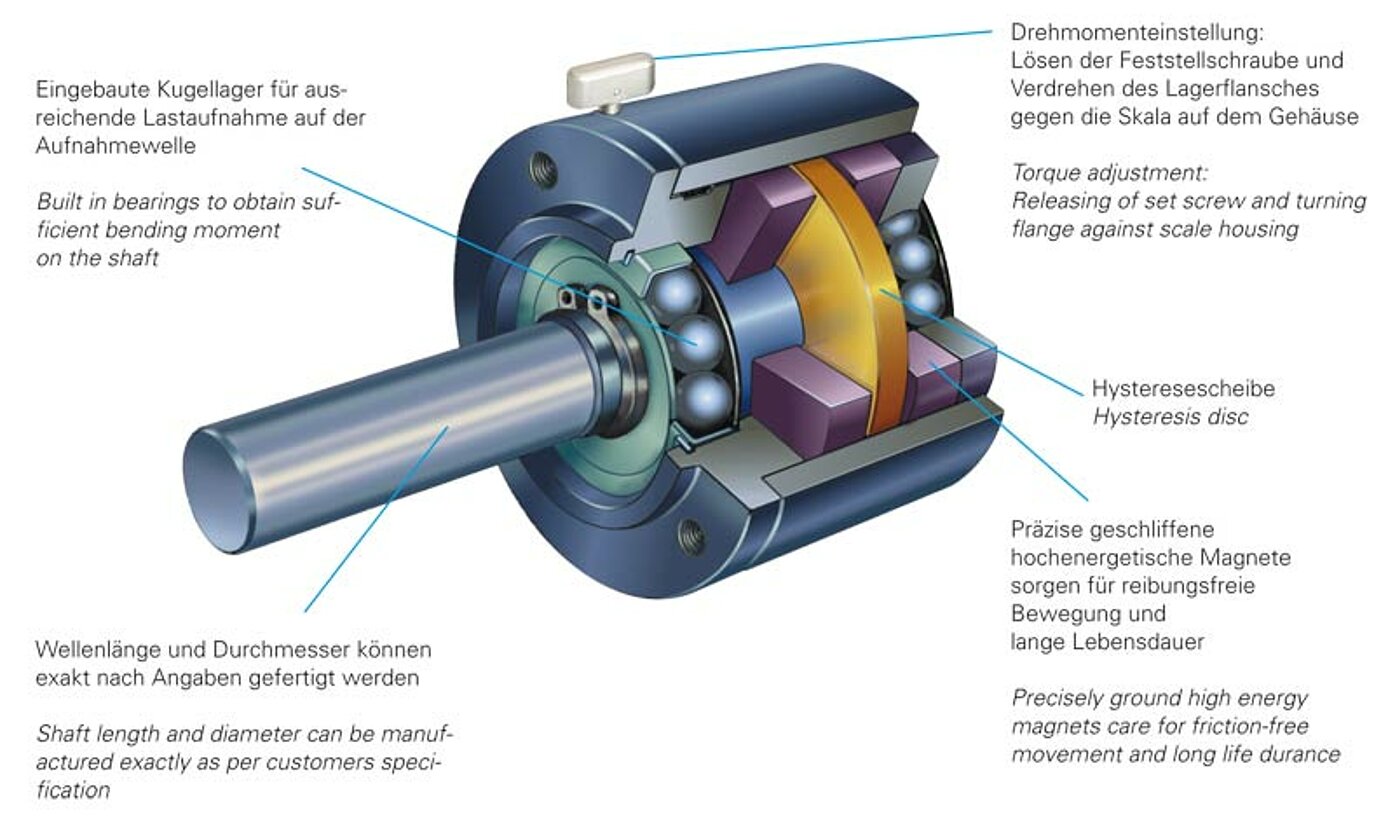

Advantages of permanent magnet hysteresis brakes

Built in ball bearings enable the units to carry sufficient load on the shaft

Shaft length and diameter can be manufactured exactly as per customers requirements

Precise adjustments of torque care for best repeatability of torque

Precise ground strong enough magnets care for friction-free movement and long lifetime

Applications with hysteresis brakes

- Tension adjustment with thin wire also after anealing

- Tension adjustment at winding wire with high sensibility

- Use as torque limitor * Adjustable torque load on test benches

- On bunching machines as improvement for tension equalizing of the in-running wires