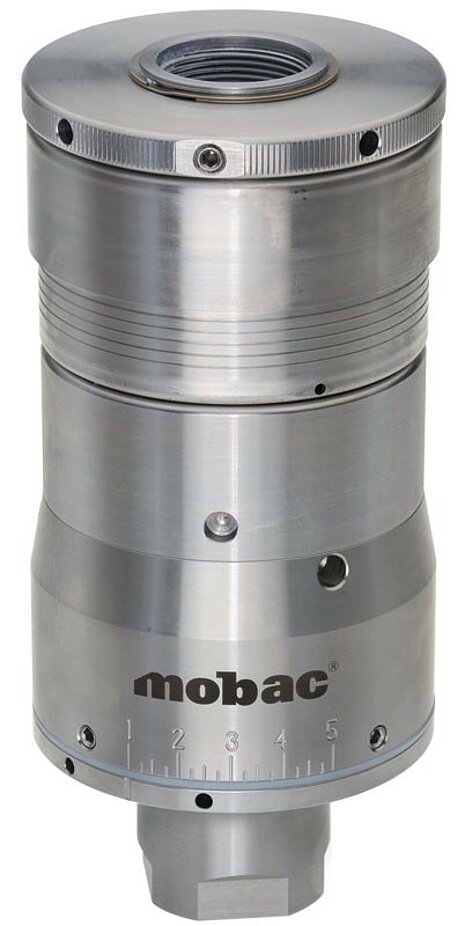

Clutches for beverage and water

- Torque available in two ranges: 0.7 - 2.6 Nm and 1.1 - 3.4 Nm

- max. 25 mm hole through the middle for air or push rod assembly

- sealed for washdown service

- easy torque adjustment with indexed scale

- designed to fit and replace most popular brands

- independently adjustable top loading spring

- available with different connection sizes

- stainless steel construction

- weight: 4.5 kg

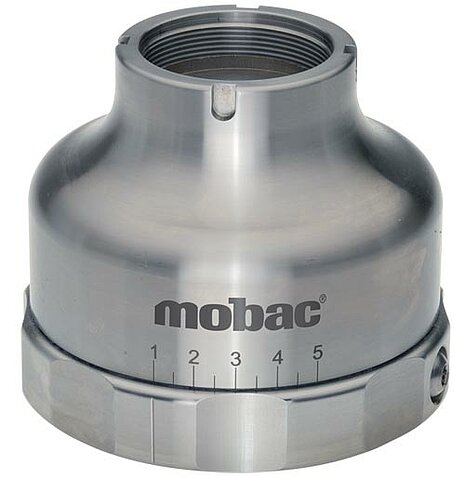

Clutches for beverage and water

- torque available in two ranges: 0.4 - 2.8 Nm and 0.9 - 3.5 Nm

- max. 19 mm hole through the middle for air or push rod assembly

- sealed for washdown service

- easy torque adjustment with indexed scale

- available with different connection sizes

- stainless steel construction

- weight: 3.2 kg

Catalog-Download (PDF)

for Bottle Capping Units

(Size approx. 1,5MB)