DP-250/560AT

Driven tangential pay-off with:

- Wire break sensor

- Protective hood

- Deflection roller for smooth wire feed etc.

Ø spool: 250 - 560 mm

Three phase motor with frequency converter: max. 2,2 kW

max. wire speed: 350 m/min

Ø of winding material: 0,1 - 1,2 mm

max. weight of spool: max. 400 kg

Wire tension: 1 N - 50 N

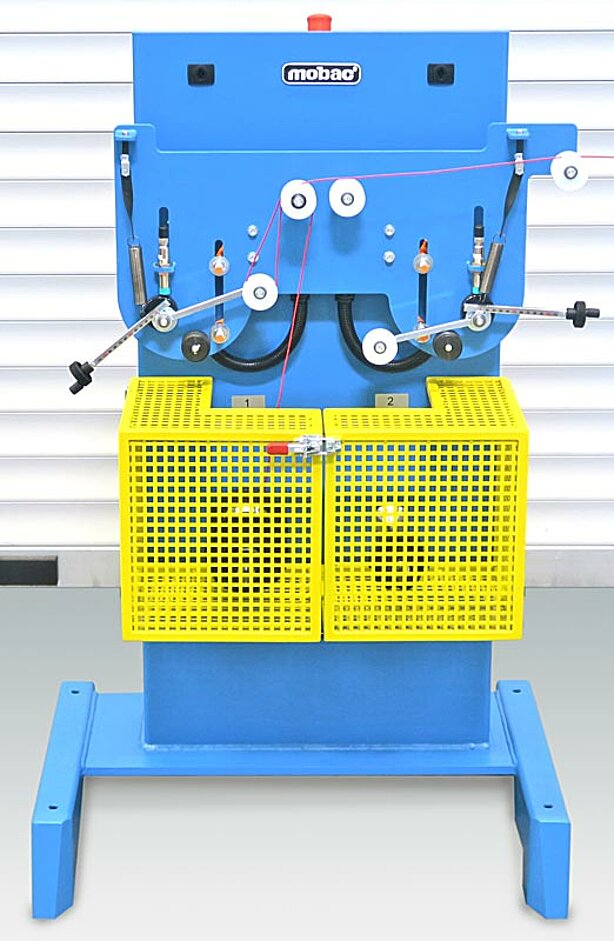

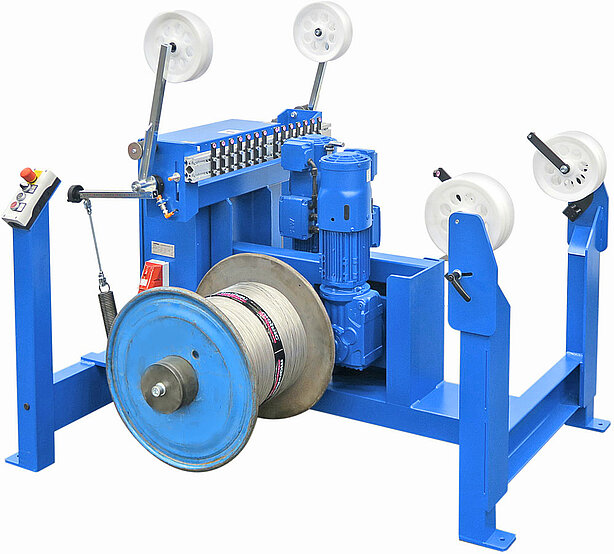

DP2-355/560AT

Driven tangential pay-off for two spoolseats with wire break sensor

Protective hood as an option

Ø spool: 355 - 560 mm

Three phase motor with frequency converter: max. 2,2 kW

max. wire speed: 300 m/min

Ø of winding material: 0,1 - 1,0 mm

max. weight of spool: max. 200 kg

Wire tension: 1 N - 50 N

DP-400/760AT

Driven tangential pay-off with:

- Wire break sensor

- Protective hood

- Deflection roller for smooth wire feed etc.

Ø spool: 450 - 600 mm

Three phase motor with frequency converter: max. 3 kW

max. wire speed: 350 m/min

Ø of winding material: 0,2 - 1,5 mm

max. weight of spool: max. 500 kg

Wire tension: 4 N - 80 N

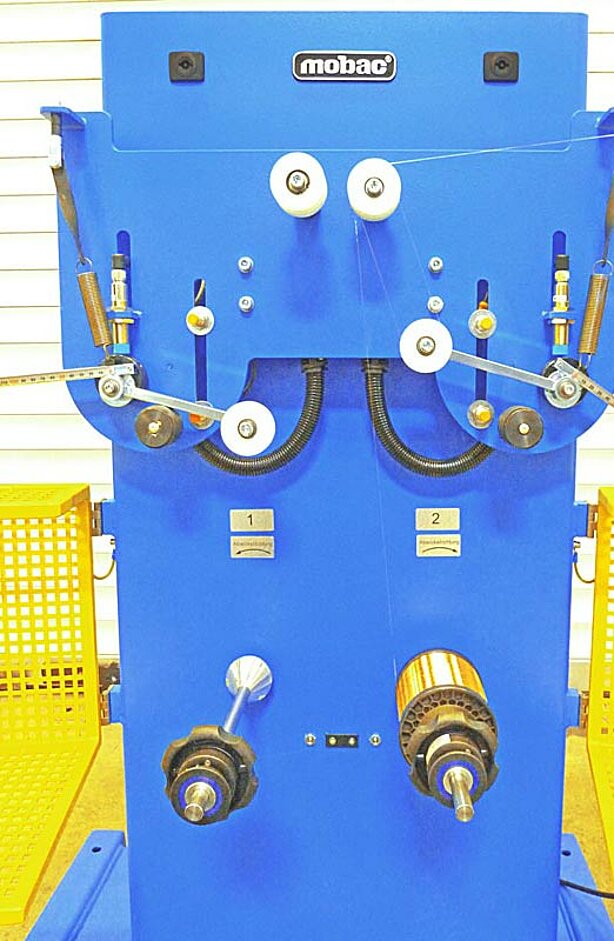

DP2-560/760AT

Driven tangential pay-off for 2 spoolseats with:

- Wire break sensor

- Protective hood

- Deflection roller for smooth wire feed etc.

Ø spool: 560 - 700 mm

Three phase motor with frequency converter: max. 3 kW

max. wire speed: 300 m/min

Ø of winding material: 0,4 - 2 mm

max. weight of spool: max. 600 kg

Wire tension: 5 - 100 N

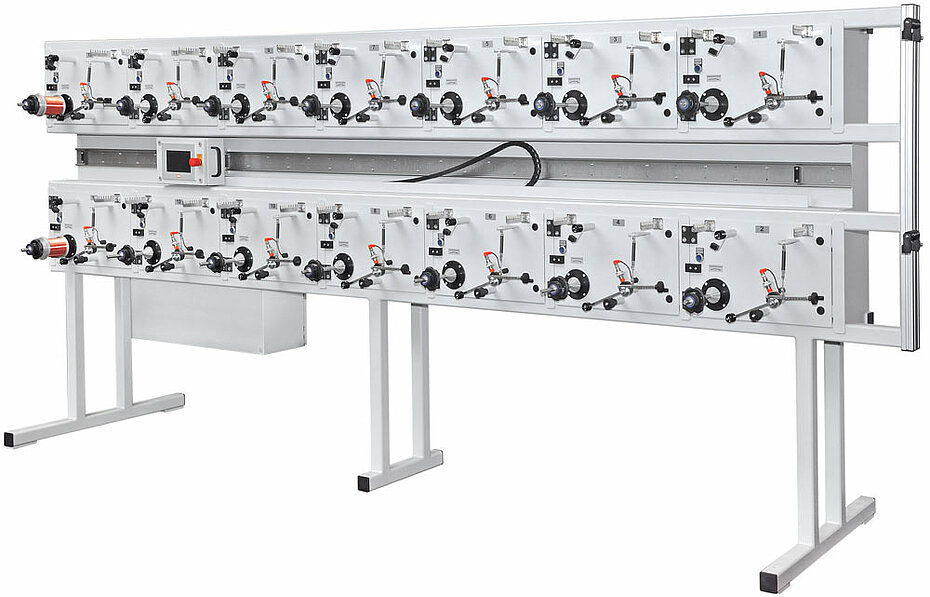

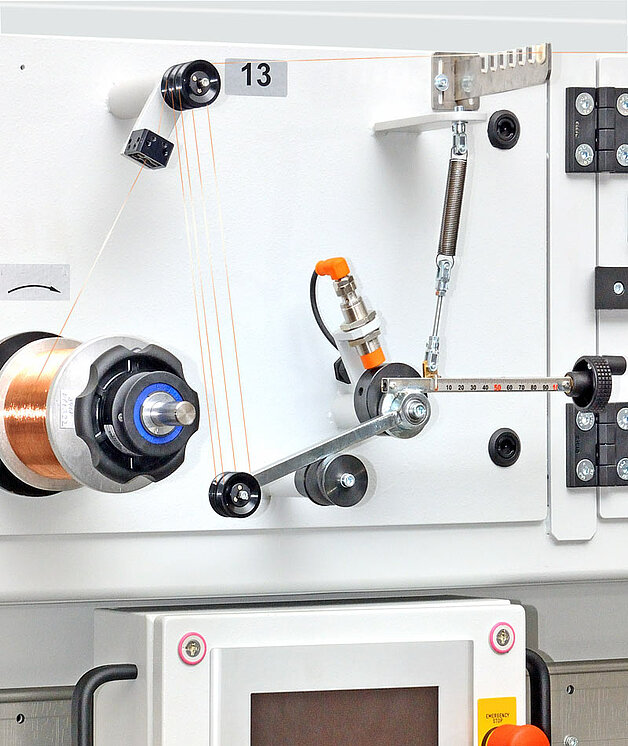

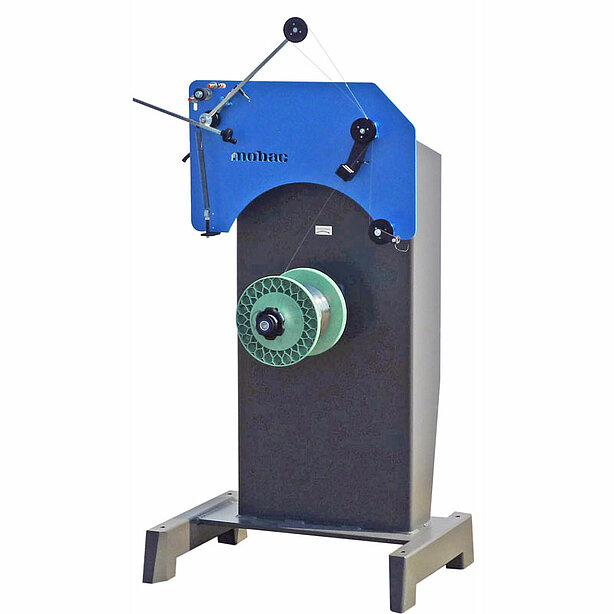

DP-80/200AT

Driven Tangential Payoff

This Payoff enables wire to run from spools with Ø 80 - 200 mm. It is built as a modulus design unit with transparent shielding and working-signal light. The winding speed is controlled by dancer arm and adapted to the following working process. The tension is adjusted by spring load of the dancer.

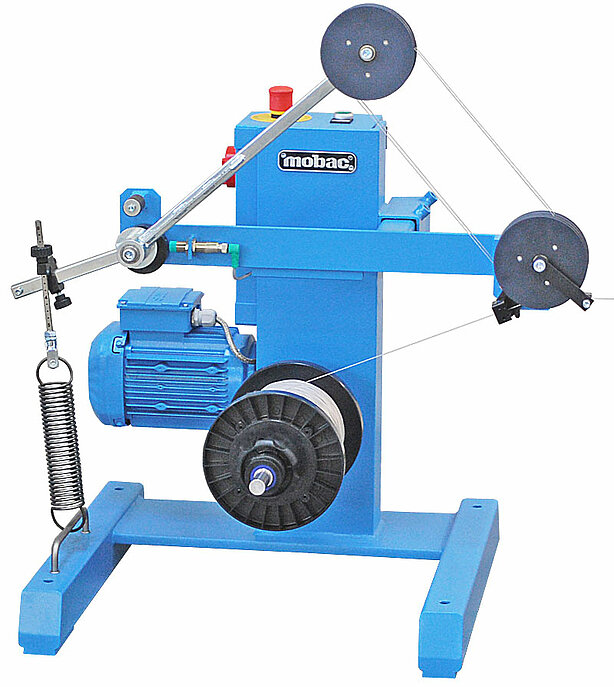

DP-80/400 AT

Driven Tangential Payoff

This Driven Tangential Payoff with tension and rpm control by sensor and dancer is used to feed extrusion lines and bunching machines as well as stranding machines.

The spools shaft with bearings on one side is driven by an AC synchronous motor with freqency inverter.

Available with or without frame rollers.

The spools are clamped with an Easylock clamping system.

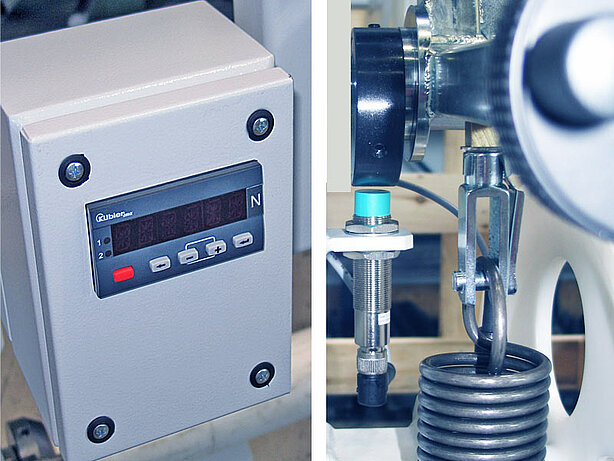

DP-160/500AT

Driven Tangential Payoff

This Driven Tangential Payoff with tension and rpm control by sensor and dancer is used to feed extrusion lines and bunching machines as well as stranding machines.

The spools shaft with bearings on one side is driven by an AC synchronous motor with freqency inverter.

The spools are clamped with an Easylock clamping system.

Wire break monitoring as an option.

DPC-400/800AT

Coil unwinder for wire, stainless steel wire

Ø Coil: 400 - 800 mm outside

Three-phase motor with frequency converter:

0,75 - 1,5 KW / 230 V / 16 A

Winding spindle speed: max. 200 min

Diameter range of the winding material: Ø 0,4 - 2,5 mm

max. coil weight: max. 250 kg

Adjustment range inside: Ø 250 - 500 mm

DP-710/780AT

Driven Tangential Payoff with tension and rpm control by dancer via sensor and tension spring.

The spools are clamped with an Easylock clamping system.

Also suitable for single steel wire

Flange Ø: 710 (500 - 800 mm optional)

Ø Single wire: 0,5 - 3 mm

Ø Multiwire: max. 10 mm2

Wire speed: max. 350 m/min